Composition and Characteristics

The outstanding performance of 310S stainless steel is due to its carefully balanced chemical composition, which typically includes:

Chromium (Cr):24-26%

Nickel (Ni):19-22%

Carbon (C):0.08% max

Manganese (Mn):2% max

Silicon (Si):1.5% max

Phosphorus (P):0.045% max

Sulfur (S):0.03% max

The high chromium and nickel content provide 310S stainless steel with its excellent resistance to oxidation and corrosion, even in environments with severe temperature fluctuations. The lower carbon content reduces the likelihood of carbide precipitation during welding, maintaining the material’s strength and corrosion resistance.

Key Properties

310S stainless steel bar is known for several key properties that make it an ideal material for challenging applications:

Superior High-Temperature Resistance:310S stainless steel can withstand continuous exposure to high temperatures up to 1150°C (2102°F) and intermittent exposure to 1035°C (1900°F), making it suitable for use in extreme heat environments where other stainless steels might fail.

Excellent Oxidation Resistance:The alloy’s high chromium and nickel content ensure outstanding resistance to oxidation and scaling, even at elevated temperatures, allowing it to maintain its structural integrity and appearance over time.

Good Corrosion Resistance:In addition to its heat resistance, 310S stainless steel also offers good corrosion resistance in a variety of environments, including those involving acids and chlorides, making it versatile for different applications.

Enhanced Weldability:The low carbon content of 310S stainless steel minimizes the risk of carbide precipitation during welding, reducing the chances of intergranular corrosion and making it easier to achieve strong, durable welds.

High Strength and Durability:The material maintains its mechanical strength even at elevated temperatures, providing reliable performance and long-term durability in demanding applications.

Applications of 310S Stainless Steel Bar

310S stainless steel bar is widely used in industries that require materials capable of withstanding high temperatures and corrosive environments. Some of the most common applications include:

Furnace Components:310S stainless steel is frequently used in the construction of industrial furnaces, radiant tubes, and heat treatment equipment due to its ability to resist oxidation and maintain strength at high temperatures.

Petrochemical Industry:The material is ideal for use in the petrochemical industry, where it is employed in components such as reformer tubes, heat exchangers, and other equipment exposed to high temperatures and corrosive gases.

Power Generation:310S stainless steel is used in power plants for components such as superheater tubes, boiler tubes, and other high-temperature equipment where resistance to oxidation and thermal stress is critical.

Chemical Processing:The alloy is also used in chemical processing equipment, particularly where exposure to corrosive chemicals at high temperatures is common.

Food Processing:310S stainless steel is employed in food processing equipment that operates at high temperatures, such as in ovens, heat exchangers, and other thermal processing units.

Advantages of Choosing 310S Stainless Steel Bar

When selecting a material for high-temperature applications, 310S stainless steel bar offers several significant advantages:

Outstanding High-Temperature Performance:310S stainless steel is engineered to maintain its structural integrity and resist oxidation even at extreme temperatures, ensuring long-term reliability in challenging environments.

Versatility Across Applications:The alloy’s ability to perform well in both high-temperature and corrosive environments makes it suitable for a wide range of industries, from petrochemical to food processing.

Improved Weldability:The lower carbon content of 310S stainless steel reduces the risk of carbide precipitation during welding, making it easier to achieve high-quality welds without compromising corrosion resistance.

Durability and Longevity:The combination of strength, oxidation resistance, and corrosion resistance ensures that components made from 310S stainless steel have a long service life, reducing maintenance costs and downtime.

Conclusion

310S stainless steel bar is a premium material designed to excel in high-temperature and corrosive environments. Whether you are working on furnace components, petrochemical equipment, or food processing units, 310S stainless steel offers the durability, strength, and resistance needed to ensure reliable performance under the most demanding conditions. Explore our range of 310S stainless steel bars today and find the perfect material for your high-temperature applications.

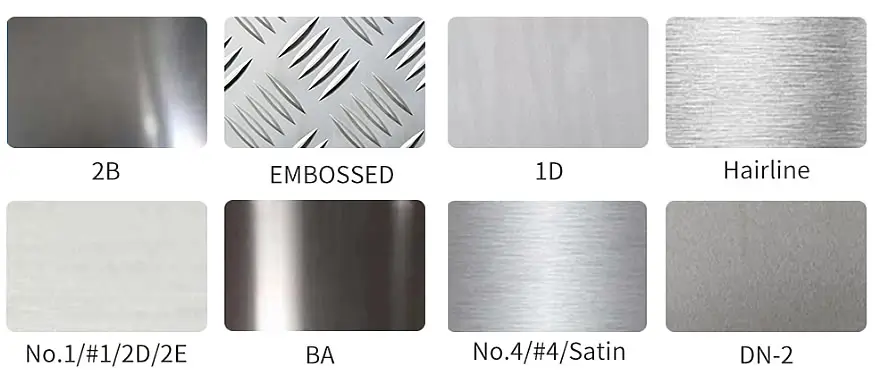

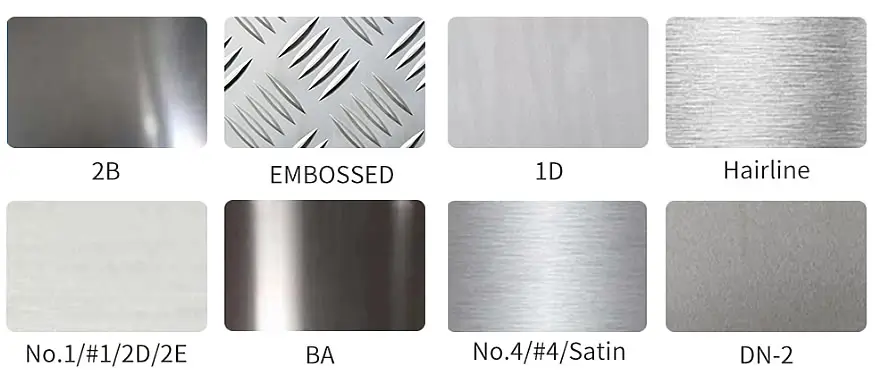

Common Surfaces

Stainless Steel Standards Comparison Table

| STS |

USA |

UNS |

CHINA |

EURONORM |

RUSSIA |

SWEDISH |

JAPANESE |

| GRADE |

AISI/ASTM |

NO |

GB |

NO |

NAME |

GOST |

SS |

JIS |

| 201 |

201 |

S20100 |

12Cr17Mn6Ni5N |

1.4372 |

- |

- |

- |

SUS 201 |

| 301 |

301 |

S30100 |

12Cr17Ni7 |

1.4310 |

X 12 CrNi 17 7 |

- |

2331 |

SUS 301 |

| 303 |

303 |

S30300 |

1Cr18Ni9MoZr |

1.4305 |

X 10 CrNiS 18 9 |

- |

2346 |

SUS 303 |

| 304 |

304 |

S30400 |

06Cr18Ni9 |

1.4301 |

X 6 CrNi 18 10 |

08KH18N10

06KH18N11 |

2332 |

SUS 304 |

| 304L |

304L |

S30403 |

022Cr19Ni10 |

1.4307 |

X 3 CrNi 18 10 |

03KH18N11 |

2352 |

SUS 304L |

| 316 |

316 |

S31600 |

0Cr17Ni12Mo2 |

1.4401 |

X 6 CrNiMo 17 12 2 |

- |

2347 |

SUS 316 |

| 316L |

316L |

S31603 |

022Cr17Ni12Mo2 |

1.4404 |

X 3 CrNiMo 17 12 2 |

- |

2348 |

SUS 316L |

| 316Ti |

316Ti |

S31635 |

0Cr18Ni12Mo2Ti |

1.4571 |

X 6 CrNiMoTi 17 12 2 |

08KH17N13M2T

10KH17N13M2T |

2350 |

- |

| 321 |

321 |

S32100 |

0Cr18Ni11Ti |

1.4541/1.4878 |

X 6 CrNiTi 18 10 |

12KH18N10T |

2337 |

SUS 321 |

| 347 |

347 |

S34709 |

0Cr18Ni11Nb |

1.4550 |

X 6 CrNiNb 18 10 |

- |

2338 |

SUS 347 |

| 309S |

309S |

S30908 |

0Cr23N13 |

1.4833 |

X 6 CrNi 22 13 |

20KH23N18 |

- |

SUS 309S |

| 310S |

310S |

S31008 |

06Cr25Ni20 |

1.4842 |

X 6 CrNi 25 20 |

20KH25N20S2 |

2361 |

SUS 310S |

| 416 |

416 |

S41600 |

Y1Cr13 |

1.4005 |

X12CrS13 |

- |

2380 |

SUS 416 |

| 2205 |

2205 |

S32205/S31803 |

00Cr22Ni5Mo3N |

1.4462 |

X2CrNiMoN22-5-3 |

02Ch22N5AM2 |

2377 |

SUS 329J3L |

| 2507 |

2507 |

S32750 |

00Cr25Ni7Mo4N |

1.4410 |

X 2 CrNiMoN 25-7-4 |

- |

- |

- |

| 904L |

904L |

N08904 |

- |

1.4539 |

- |

- |

- |

- |

| 254SMO |

254SMO |

S31254 |

- |

1.4547 |

X1CrNiMoCuN20-18-7 |

- |

2378 |

- |

| 253MA |

253MA |

S30815 |

- |

1.4835 |

X9CrNiSiNCe21-11-2 |

- |

2368 |

- |

| 17-4PH/630 |

17-4PH/630 |

S17400 |

0Cr17Ni4Cu4Nb |

1.4542 |

X5CrNiCuNb16-4 |

05Ch16N4D2B |

- |

SUS630 |