430 Stainless Steel Pipe/Tube Details

Overview

430 stainless steel pipe/tube is a ferritic stainless steel known for its good corrosion resistance, formability, and relatively low cost. It is primarily used in applications where moderate corrosion resistance is required, along with good mechanical properties and ease of fabrication.

Key Characteristics

Corrosion Resistance: Provides good resistance to oxidation and corrosion in moderately corrosive environments, including mildly acidic and alkaline conditions.

Formability: Offers excellent formability and can be easily shaped and fabricated into various forms and sizes, making it suitable for a wide range of applications.

Magnetic Properties: Magnetic due to its ferritic structure, which is a key characteristic for certain applications.

Heat Resistance: Maintains reasonable performance at moderately elevated temperatures but is not as heat-resistant as some other grades.

Weldability: Can be welded using standard techniques, though preheating and post-weld heat treatment are generally not required for most applications.

Chemical Composition

Carbon (C): ≤ 0.12%

Manganese (Mn): 1.00%

Silicon (Si): ≤ 1.00%

Phosphorus (P): ≤ 0.040%

Sulfur (S): ≤ 0.030%

Chromium (Cr): 16.00-18.00%

Nickel (Ni): ≤ 0.75%

Common Applications

Home Appliances: Used in the manufacture of kitchen appliances and other household items where moderate corrosion resistance and good formability are needed.

Automotive Parts: Applied in automotive exhaust systems and trim components due to its resistance to oxidation and ease of fabrication.

Architectural Applications: Employed in architectural components and decorative elements where appearance and moderate corrosion resistance are important.

Industrial Equipment: Suitable for industrial equipment and machinery parts that require moderate corrosion resistance and durability.

Advantages

Good Corrosion Resistance: Provides reliable performance in mildly corrosive environments, making it suitable for various industrial and consumer applications.

Excellent Formability: Easily fabricated into different shapes and sizes, allowing for versatile use in manufacturing processes.

Cost-Effective: Offers a balance of performance and affordability, making it a practical choice for applications where high corrosion resistance is not the primary concern.

Magnetic Properties: Magnetic characteristics are beneficial for certain applications, such as magnetic separators or components that require magnetic properties.

Summary

430 stainless steel pipe/tube is a ferritic stainless steel known for its good corrosion resistance, excellent formability, and cost-effectiveness. Its chemical composition and properties make it suitable for a range of applications, including home appliances, automotive parts, architectural components, and industrial equipment. With its combination of moderate corrosion resistance, easy fabrication, and affordability, 430 stainless steel is a versatile choice for various applications.

For more detailed information or specific inquiries about 430 stainless steel pipe/tube, please contact us.

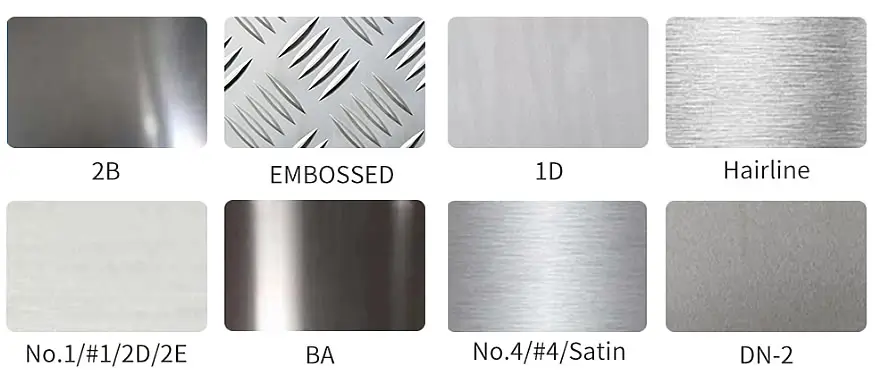

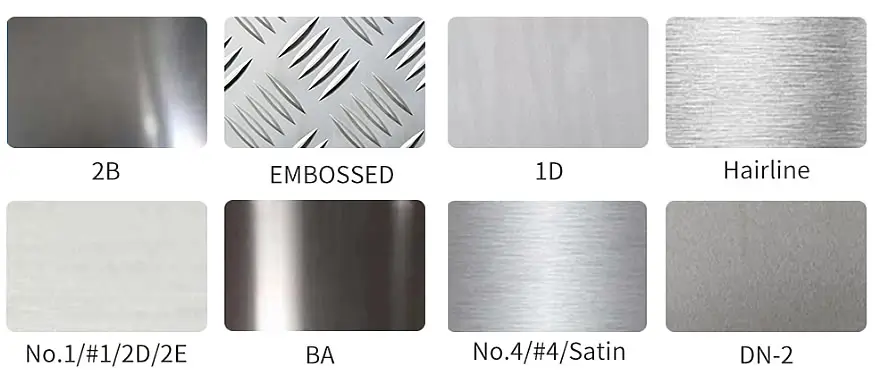

Common Surfaces

Stainless Steel Standards Comparison Table

| STS |

USA |

UNS |

CHINA |

EURONORM |

RUSSIA |

SWEDISH |

JAPANESE |

| GRADE |

AISI/ASTM |

NO |

GB |

NO |

NAME |

GOST |

SS |

JIS |

| 201 |

201 |

S20100 |

12Cr17Mn6Ni5N |

1.4372 |

- |

- |

- |

SUS 201 |

| 301 |

301 |

S30100 |

12Cr17Ni7 |

1.4310 |

X 12 CrNi 17 7 |

- |

2331 |

SUS 301 |

| 303 |

303 |

S30300 |

1Cr18Ni9MoZr |

1.4305 |

X 10 CrNiS 18 9 |

- |

2346 |

SUS 303 |

| 304 |

304 |

S30400 |

06Cr18Ni9 |

1.4301 |

X 6 CrNi 18 10 |

08KH18N10

06KH18N11 |

2332 |

SUS 304 |

| 304L |

304L |

S30403 |

022Cr19Ni10 |

1.4307 |

X 3 CrNi 18 10 |

03KH18N11 |

2352 |

SUS 304L |

| 316 |

316 |

S31600 |

0Cr17Ni12Mo2 |

1.4401 |

X 6 CrNiMo 17 12 2 |

- |

2347 |

SUS 316 |

| 316L |

316L |

S31603 |

022Cr17Ni12Mo2 |

1.4404 |

X 3 CrNiMo 17 12 2 |

- |

2348 |

SUS 316L |

| 316Ti |

316Ti |

S31635 |

0Cr18Ni12Mo2Ti |

1.4571 |

X 6 CrNiMoTi 17 12 2 |

08KH17N13M2T

10KH17N13M2T |

2350 |

- |

| 321 |

321 |

S32100 |

0Cr18Ni11Ti |

1.4541/1.4878 |

X 6 CrNiTi 18 10 |

12KH18N10T |

2337 |

SUS 321 |

| 347 |

347 |

S34709 |

0Cr18Ni11Nb |

1.4550 |

X 6 CrNiNb 18 10 |

- |

2338 |

SUS 347 |

| 309S |

309S |

S30908 |

0Cr23N13 |

1.4833 |

X 6 CrNi 22 13 |

20KH23N18 |

- |

SUS 309S |

| 310S |

310S |

S31008 |

06Cr25Ni20 |

1.4842 |

X 6 CrNi 25 20 |

20KH25N20S2 |

2361 |

SUS 310S |

| 416 |

416 |

S41600 |

Y1Cr13 |

1.4005 |

X12CrS13 |

- |

2380 |

SUS 416 |

| 2205 |

2205 |

S32205/S31803 |

00Cr22Ni5Mo3N |

1.4462 |

X2CrNiMoN22-5-3 |

02Ch22N5AM2 |

2377 |

SUS 329J3L |

| 2507 |

2507 |

S32750 |

00Cr25Ni7Mo4N |

1.4410 |

X 2 CrNiMoN 25-7-4 |

- |

- |

- |

| 904L |

904L |

N08904 |

- |

1.4539 |

- |

- |

- |

- |

| 254SMO |

254SMO |

S31254 |

- |

1.4547 |

X1CrNiMoCuN20-18-7 |

- |

2378 |

- |

| 253MA |

253MA |

S30815 |

- |

1.4835 |

X9CrNiSiNCe21-11-2 |

- |

2368 |

- |

| 17-4PH/630 |

17-4PH/630 |

S17400 |

0Cr17Ni4Cu4Nb |

1.4542 |

X5CrNiCuNb16-4 |

05Ch16N4D2B |

- |

SUS630 |