436 Stainless Steel Pipe/Tube Details

Overview

436 stainless steel pipe/tube is a ferritic stainless steel alloy designed for applications requiring improved corrosion resistance compared to standard ferritic grades. It offers a balance of corrosion resistance, formability, and cost-effectiveness, making it suitable for various industrial and commercial uses.

Key Characteristics

Corrosion Resistance: Provides better resistance to oxidation and corrosion compared to basic ferritic grades. It performs well in mildly corrosive environments and offers improved resistance to oxidation at elevated temperatures.

Formability: Good formability allows it to be easily shaped and fabricated into various forms and sizes, suitable for diverse applications.

Magnetic Properties: Magnetic due to its ferritic structure, which can be advantageous for applications requiring magnetic properties.

Heat Resistance: Maintains reasonable performance at moderately high temperatures, though it is not as heat-resistant as some austenitic grades.

Weldability: Can be welded using standard techniques; however, it is generally less suitable for welding compared to austenitic grades. Proper procedures should be followed to ensure weld quality.

Chemical Composition

Carbon (C): ≤ 0.08%

Manganese (Mn): 1.00%

Silicon (Si): ≤ 1.00%

Phosphorus (P): ≤ 0.040%

Sulfur (S): ≤ 0.030%

Chromium (Cr): 16.00-18.00%

Nickel (Ni): ≤ 0.75%

Common Applications

Automotive Components: Used in automotive exhaust systems and trim parts where good corrosion resistance and durability are needed.

Industrial Equipment: Applied in various industrial equipment and machinery parts that benefit from moderate corrosion resistance and formability.

Architectural Applications: Suitable for architectural features and decorative elements where appearance and corrosion resistance are important.

Consumer Goods: Employed in consumer products such as kitchen appliances and household items where moderate corrosion resistance is sufficient.

Advantages

Enhanced Corrosion Resistance: Offers improved resistance to oxidation and corrosion compared to standard ferritic grades, making it suitable for moderately corrosive environments.

Good Formability: Can be easily fabricated into different shapes and sizes, allowing for flexibility in manufacturing processes.

Cost-Effective: Provides a balance of performance and affordability, making it a practical choice for various applications where high corrosion resistance is not the primary requirement.

Magnetic Properties: Useful in applications that require magnetic characteristics.

Summary

436 stainless steel pipe/tube is a ferritic stainless steel known for its improved corrosion resistance, good formability, and cost-effectiveness. Its chemical composition and properties make it suitable for a variety of applications, including automotive components, industrial equipment, architectural features, and consumer goods. With its combination of enhanced corrosion resistance, formability, and affordability, 436 stainless steel is a versatile choice for applications requiring moderate performance.

For more detailed information or specific inquiries about 436 stainless steel pipe/tube, please contact us.

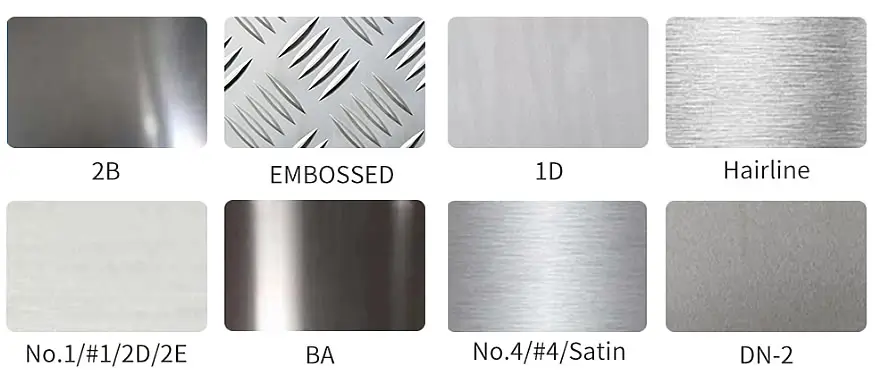

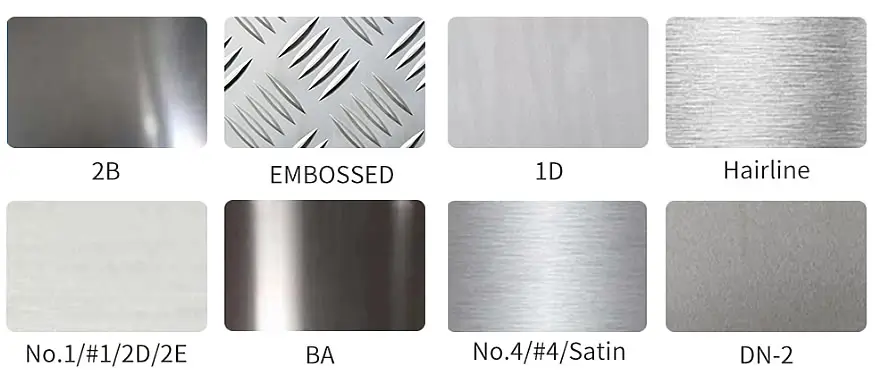

Common Surfaces

Stainless Steel Standards Comparison Table

| STS |

USA |

UNS |

CHINA |

EURONORM |

RUSSIA |

SWEDISH |

JAPANESE |

| GRADE |

AISI/ASTM |

NO |

GB |

NO |

NAME |

GOST |

SS |

JIS |

| 201 |

201 |

S20100 |

12Cr17Mn6Ni5N |

1.4372 |

- |

- |

- |

SUS 201 |

| 301 |

301 |

S30100 |

12Cr17Ni7 |

1.4310 |

X 12 CrNi 17 7 |

- |

2331 |

SUS 301 |

| 303 |

303 |

S30300 |

1Cr18Ni9MoZr |

1.4305 |

X 10 CrNiS 18 9 |

- |

2346 |

SUS 303 |

| 304 |

304 |

S30400 |

06Cr18Ni9 |

1.4301 |

X 6 CrNi 18 10 |

08KH18N10

06KH18N11 |

2332 |

SUS 304 |

| 304L |

304L |

S30403 |

022Cr19Ni10 |

1.4307 |

X 3 CrNi 18 10 |

03KH18N11 |

2352 |

SUS 304L |

| 316 |

316 |

S31600 |

0Cr17Ni12Mo2 |

1.4401 |

X 6 CrNiMo 17 12 2 |

- |

2347 |

SUS 316 |

| 316L |

316L |

S31603 |

022Cr17Ni12Mo2 |

1.4404 |

X 3 CrNiMo 17 12 2 |

- |

2348 |

SUS 316L |

| 316Ti |

316Ti |

S31635 |

0Cr18Ni12Mo2Ti |

1.4571 |

X 6 CrNiMoTi 17 12 2 |

08KH17N13M2T

10KH17N13M2T |

2350 |

- |

| 321 |

321 |

S32100 |

0Cr18Ni11Ti |

1.4541/1.4878 |

X 6 CrNiTi 18 10 |

12KH18N10T |

2337 |

SUS 321 |

| 347 |

347 |

S34709 |

0Cr18Ni11Nb |

1.4550 |

X 6 CrNiNb 18 10 |

- |

2338 |

SUS 347 |

| 309S |

309S |

S30908 |

0Cr23N13 |

1.4833 |

X 6 CrNi 22 13 |

20KH23N18 |

- |

SUS 309S |

| 310S |

310S |

S31008 |

06Cr25Ni20 |

1.4842 |

X 6 CrNi 25 20 |

20KH25N20S2 |

2361 |

SUS 310S |

| 416 |

416 |

S41600 |

Y1Cr13 |

1.4005 |

X12CrS13 |

- |

2380 |

SUS 416 |

| 2205 |

2205 |

S32205/S31803 |

00Cr22Ni5Mo3N |

1.4462 |

X2CrNiMoN22-5-3 |

02Ch22N5AM2 |

2377 |

SUS 329J3L |

| 2507 |

2507 |

S32750 |

00Cr25Ni7Mo4N |

1.4410 |

X 2 CrNiMoN 25-7-4 |

- |

- |

- |

| 904L |

904L |

N08904 |

- |

1.4539 |

- |

- |

- |

- |

| 254SMO |

254SMO |

S31254 |

- |

1.4547 |

X1CrNiMoCuN20-18-7 |

- |

2378 |

- |

| 253MA |

253MA |

S30815 |

- |

1.4835 |

X9CrNiSiNCe21-11-2 |

- |

2368 |

- |

| 17-4PH/630 |

17-4PH/630 |

S17400 |

0Cr17Ni4Cu4Nb |

1.4542 |

X5CrNiCuNb16-4 |

05Ch16N4D2B |

- |

SUS630 |